Finishing & Materials

Offset Printing

Offset printing is suitable for your large-scale printing project.

Customization Options

Digital Printing

Customization Options

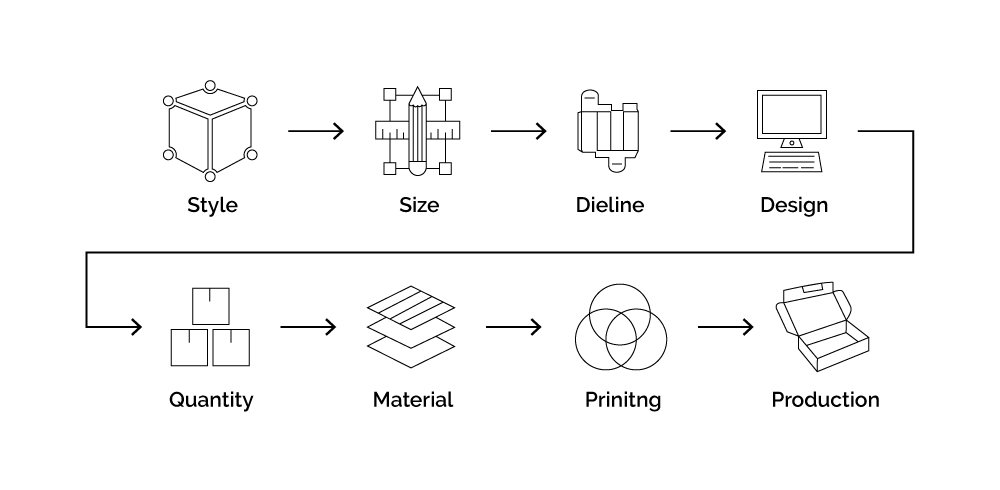

Our Packaging and Prinitng Process

Different Packaging Options

Indeed, we care about the environment, providing eco-friendly packaging for your products. For crafting custom packaging that makes an impression, use premium paper options. Our team utilizes recycled paperboard, kraft paper, and corrugated cardboard, etc.

Our team will help contribute to a greener future by reducing your carbon footprint on the environment. Create a sense of anticipation in your customers with our finest quality custom printed boxes. Make their unboxing experience memorable and exciting.

How Printinglance Serves You?

PrintingGlance has various solutions for your custom printed boxes. We are committed to providing unmatched packaging that will leave a lasting impression on your customers.

With wide-ranging customization options, excellent printing quality, and extraordinary customer service. We take pride in providing excellent services for you that are both affordable and efficient. With us, You can get customized solutions that suit your unique requirements, including eco-friendly materials and special finishing options. Regardless of the size of your business, our website serves as a one-stop shop for all your needs. Uplift your brand today!

Frequently Asked Questions

We've got you covered! All your pre-order questions have been answered. Do you have any questions about our boxes? Feel free to ask!

You can easily place your order by contacting our sales team through sales@printinglance.com | +1 786 927 5086 Our representatives will guide you through the ordering process step by step.